TRANSFORM YOUR GREATEST CHALLENGES INTO OPPORTUNITIES

Improving plant productivity through efficient use of resources is a key factor in the chemicals and plastics industry today.

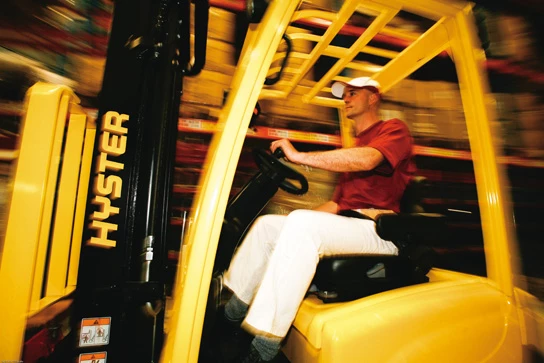

SAFETY

Your industry is highly regulated, and workers often operate around hazardous materials. Reducing the risk of damage and spills is critical.

How can you meet OSHA requirements and help protect your employees?

- Use telematics to track lift truck access and provide training updates

- Evaluate whether forklift awareness solutions like lights and alarms will help increase alertness and minimize risk in your facility

- Deploy operator assist technology to help reinforce operating best practices in real time

- Implement automated solutions and redirect workers to more value added tasks

- Help prevent ignition of substances in chemical applications with potentially explosive atmospheres by using certified explosion-proof (EX) lift trucks

AWKWARD LOADS

Chemicals and plastics operations often handle several types of awkward and non-palletized loads, from bags of raw materials and long pipes to drums, barrels and intermediate bulk containers (IBC).

How can you improve productivity and minimize damage?

- Prioritize precision and confidence with forklifts engineered with robust masts, high visibility and maneuverability

- Optimize operator performance with intuitive controls and fork positioners that help them handle a variety of loads without exiting the cabin

- Help reduce the likelihood of incidents and spills by deploying trucks with advanced stability systems

SUSTAINABILITY

The chemicals and plastics industry has been increasing efforts toward sustainability, but meeting the demands of customers and government agencies remains a challenge.

Want to improve the environmental performance of your operation?

- Help maximize sustainability through fleet electrification

- Mitigate the risk of harmful explosions and spills with smooth-handling equipment

- Develop a recycling plan for by-products of your operation

RAW MATERIALS PRICING

Raw materials pricing can be volatile and out of your control, impacting your bottom line.

How can you better manage costs within your operation?

- Right-size your materials handling equipment with a fleet management plan

- Deploy energy efficient equipment

- Maximize uptime and contain costs with reliable, easy-to-maintain lift trucks with longer service intervals

LABOR RETENTION

Hiring people who are willing to learn your industry is one thing, but it’s often difficult to keep them.

How can you retain talent and help reduce turnover?

- Offer advanced ergonomic lift truck solutions to help reduce musculoskeletal problems

- Implement training and development programs to keep your team engaged

- Simplify checklists and reinforce positive behavior with telematics and operator assist technology

SPACE CONSTRAINTS

Precision handling of raw and finished goods in crowded production and storage areas is critical.

How are you going to optimize your footprint?

- Go vertical, and take advantage of unused cubic space

- Deploy compact trucks developed specifically for high lift applications in confined areas

- Utilize agile electric trucks, delivering high productivity in constrained spaces